You can know every new products be published here, and witness our growth and innovation.

Date:10-17-2022

Nominal diameter of heat shrinkable tube:

The key of the heat shrink tube is to be used as a preventive product for the cable. The cross section of the heat shrink tube is a cylindrical tube shape, so the nominal diameter is the size of the inner diameter of the wall thickness. This main parameter is related to whether it is in line with the safety protection cable. If the nominal diameter is too small, it cannot be inserted into the tube, and if it is too large, it cannot be tightly closed. The selection must be made according to the product specifications. The mark Φ indicates the diameter of the heat shrinkable tube, and the default setting is mm.

Thin-walled heat shrink tubing:

The wall thickness of the heat shrink tube means the thickness of the pipe fittings. The thickness of the pipe fittings harms the size of the safety protection of the insulating layer. Therefore, the higher the thickness of the heat shrink tube, the better the safety protection ability. In addition, the higher the thickness, the more Improving the safety protection work ability of this product can improve the compressive strength of this product, but the higher the thickness, the more inconvenient it will be. Generally, heat shrinkable tubes with high thickness and thickness are all used on some less complicated routes and products.

Shrinkage rate of heat shrinkable tube:

The shrinkage rate refers to the ratio of the nominal diameter of the heat shrink tube before it is shrunk to the nominal diameter after it is shrunk. The shrinkage rate reflects the size of the shrinkage sleeve’s ability to shrink. The tube becomes thinner when it is completely closed. Common shrinkage ratios of heat shrinkable tubes are 2:1, 3:1, and 4:1. The actual selection should be considered according to the requirements of the product.

Heat shrink tube shrinking temperature:

The shrinking of the heat-shrink tube is a whole process of gradual color, so the shrinking temperature of the heat-shrink tube is divided into the starting and shrinking temperature and the final shrinking temperature. As for the temperature at the time of shrinkage, people’s general PE heat shrinkable sleeves have a shrinkage temperature of 84°C at the beginning, that is, they have a shrinkage reaction at the beginning. The final shrinkage temperature is the temperature that can make the heat shrinkable tube exceed the complete shrinkage temperature. The heat shrinkable tube will just start shrinking when it exceeds the starting shrinkage temperature.

Heat shrink tubing application operating temperature:

The working temperature of heat shrinkable tube product must pay attention to the general working temperature of heat shrinkable tube application in the range of -55 degrees to 125 degrees. After the data information, the service life of the heat shrinkable tube and the safety protection characteristics of the insulation layer cannot be guaranteed in the natural environment after the data information.

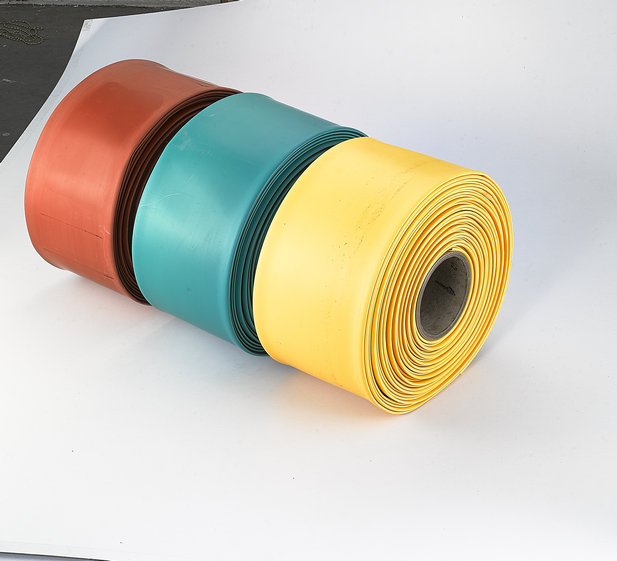

Heat Shrink Tube Shades:

The color of the heat-shrink tube does not need to be much. Customers only have to choose the color they want. Generally, heat-shrink tube manufacturers have white, gray-black, bright red, light yellow, and dark blue light tones to choose if If you are a customer with insufficient budget, it is best to choose gray and black.