You can know every new products be published here, and witness our growth and innovation.

Date:07-27-2021

High-voltage switch cabinets are widely used in power distribution systems for receiving and distributing electrical energy. Part of the power equipment or lines can be put into or out of operation according to the operation of the power grid, and the faulted part can be quickly removed from the power grid when the power equipment or line fails, so as to ensure the normal operation of the fault-free part of the power grid, as well as equipment and Safety of operation and maintenance personnel. Therefore, high-voltage switchgear is a very important power distribution equipment, and its safe and reliable operation is of great significance to the power system.

1.Classification of high voltage switchgear

Structure Type:

Armoured type All types are isolated and grounded by metal plates, such as KYN type and KGN type

Interval type All types are separated by one or more non-metallic plates, such as JYN type

Box type has a metal shell, but the number of compartments is less than that of armored market or compartment type, such as XGN type

Placement of the circuit breaker:

Floor type The circuit breaker handcart itself landed and pushed into the cabinet

The middle-mounted handcart is installed in the middle of the switch cabinet, and the loading and unloading of the handcart requires a loading and unloading car

Mid-mounted handcart

Floor handcart

Insulation type

Air insulated metal enclosed switchgear

SF6 gas insulated metal enclosed switchgear (inflatable cabinet)

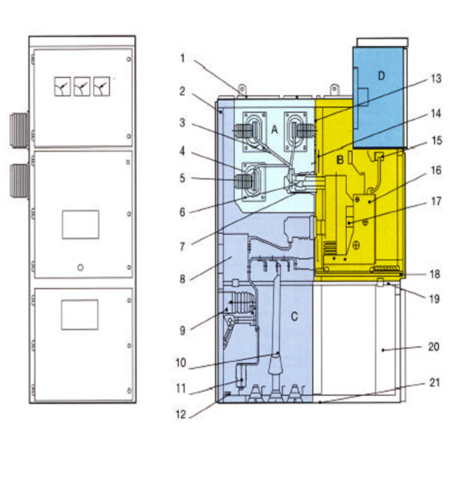

2. Composition structure of KYN high voltage switch cabinet

The switch cabinet is composed of a fixed cabinet body and withdrawable parts (referred to as a handcart)

one. Cabinet

The shell and partitions of the switchgear are made of aluminum-zinc steel plate. The whole cabinet has high precision, corrosion resistance and oxidation, but also has high mechanical strength and beautiful appearance. The cabinet adopts an assembled structure and is connected with rivet nuts and high-strength bolts. Therefore, the assembled switchgear can maintain the uniformity of dimensions.

The switch cabinet is divided into the handcart room, busbar room, cable room and relay instrument room by partitions, and each unit is well grounded.

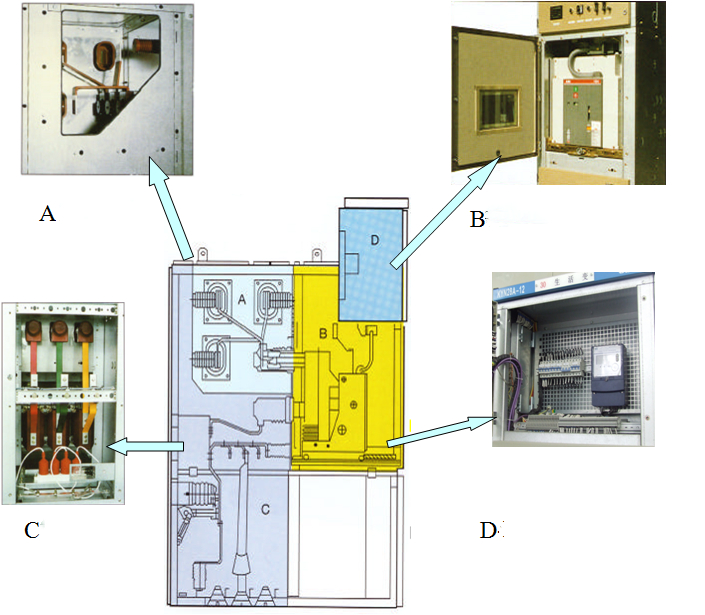

A-Bus room

The busbar room is arranged on the upper part of the back of the switch cabinet for installation and arrangement of three-phase high voltage AC busbars and for connecting with static contacts through branch busbars. All busbars are plastic-sealed with insulating sleeves. When the bus bar passes through the partition of the switch cabinet, it is fixed with a bus bushing. If an internal fault arc occurs, it can limit the spread of the accident to adjacent cabinets and ensure the mechanical strength of the busbar.

B-handcart (circuit breaker) room

A specific guide rail is installed in the circuit breaker room for the circuit breaker trolley to slide and work inside. The handcart can move between the working position and the test position. The partition (trap) of the static contact is installed on the rear wall of the handcart room. When the handcart moves from the test position to the working position, the partition is automatically opened, and the handcart is moved in the opposite direction to fully compound, thus ensuring that the operator does not touch the charged body.

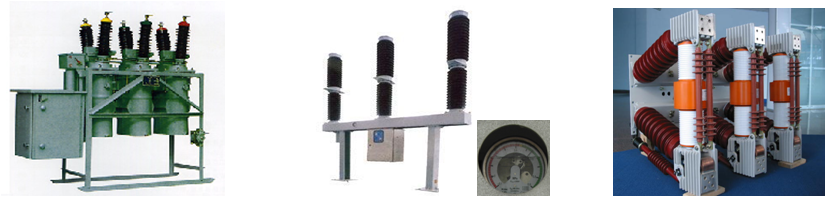

Circuit breakers can be divided into arc extinguishing media:

• Oil circuit breaker. It is divided into more oil circuit breakers and less oil circuit breakers. They are all contacts that are opened and connected in oil, and transformer oil is used as the arc extinguishing medium.

• Compressed air circuit breaker. A circuit breaker that uses high-pressure compressed air to blow out the arc.

• SF6 circuit breaker. A circuit breaker that uses SF6 gas to blow out the arc.

• Vacuum circuit breaker. A circuit breaker in which the contacts are opened and closed in vacuum, and the arc is extinguished under vacuum conditions.

•Solid gas generating circuit breaker. A circuit breaker that uses solid gas-generating materials to extinguish the arc by decomposing the gas under the action of the high temperature of the arc.

• Magnetic blower circuit breaker. A circuit breaker in which the arc is blown into the arc extinguishing grid by a magnetic field in the air, so that it is elongated and cooled to extinguish the arc.

According to the different energy forms of the operating energy used by the operating mechanism, the operating mechanism can be divided into the following types:

Manual mechanism (CS): Refers to the operating mechanism that uses human power to close the brake.

2. Electromagnetic mechanism (CD): refers to the operating mechanism that uses electromagnets to close.

3. Spring mechanism (CT): refers to a spring closing operating mechanism that uses manpower or a motor to store energy in the spring to achieve closing.

4. Motor mechanism (CJ): refers to the operating mechanism that uses a motor to close and open.

5. Hydraulic mechanism (CY): refers to the operating mechanism that uses high-pressure oil to push the piston to achieve closing and opening.

6. Pneumatic mechanism (CQ): refers to the operating mechanism that uses compressed air to push the piston to achieve closing and opening.

7. Permanent magnet mechanism: It uses permanent magnets to maintain the position of the circuit breaker. It is an electromagnetic operation, permanent magnet retention, and electronic control operating mechanism.

C-cable room

Current transformers, grounding switches, lightning arresters (overvoltage protectors), cables and other auxiliary equipment can be installed in the cable room, and a slitted and removable aluminum plate is prepared at the bottom to ensure the convenience of on-site construction.

D-relay instrument room

The panel of the relay room is equipped with microcomputer protection devices, operating handles, protective outlet pressure plates, meters, status indicators (or status displays), etc.; in the relay room, there are terminal blocks, microcomputer protection control loop DC power switches, and microcomputer protection work. DC power supply, energy storage motor working power switch (DC or AC), and secondary equipment with special requirements.

Three positions in the switchgear handcart

Working position: the circuit breaker is connected with the primary equipment. After closing, the power is transmitted from the bus to the transmission line through the circuit breaker.

Test position: The secondary plug can be inserted into the socket to obtain power supply.The circuit breaker can be closed, open operation, the corresponding indicator light;The circuit breaker has no connection with the primary equipment and can carry out various operations, but it will not have any effect on the load side, so it is called the test position.

Maintenance position: there is no contact between the circuit breaker and the primary equipment (bus), the operation power is lost (the secondary plug has been unplugged), and the circuit breaker is in the opening position.

Switch cabinet interlocking device

The switch cabinet has a reliable interlocking device to meet the requirements of five prevention, and effectively protect the safety of operators and equipment.

A. The door of the instrument room is equipped with a suggestive button or transfer switch to prevent the circuit breaker from mistakenly closing and dividing.

B, circuit breaker hand in the test position or working position, circuit breaker can be operated, and in the circuit breaker closing, hand can not move, to prevent the load of the wrong push handle car.

C. Only when the ground switch is in the opening position, the circuit breaker handcart can be moved from the test/maintenance position to the working position.Only when the circuit breaker hand truck is in the test/maintenance position, the ground switch can be operated on.In this way, it can prevent the grounding switch from being switched on by mistake, and prevent the grounding switch from being switched on by time.

D. When the ground switch is in the opening position, the lower door and the back door of the switch cabinet can not be opened to prevent accidental electrication interval.

E, circuit breaker hand in the test or working position, no control voltage, can be realized only manual opening can not close.

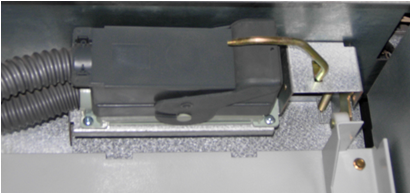

F. When the circuit breaker hand car is in the working position, the secondary plug is locked and cannot be pulled out.

G, each cabinet body can realize electrical interlock.

H. The connection between the secondary line of the switching equipment and the secondary line of the circuit breaker handcart is realized by manual secondary plug. The moving contact of the secondary plug is connected with the circuit breaker handcart through a nylon corrugated shrink tube.Circuit breaker handcar only in the test, disconnect position, can plug in and remove the second plug, circuit breaker handcar in the working position due to mechanical interlocking, the second plug is locked, can not be removed.

3. Operation procedure of high voltage switchgear

Although the switchgear design has been guaranteed switchgear operating sequence of interlocking correctly, the parts but the operator to switch equipment operation, still should strictly according to operation procedures and related requirements, should not be optional operation, more should not be stuck in operation without analysis to operation, otherwise easy to cause the equipment damage, even cause accidents.

High voltage switchgear transmission operation procedure

(1) Close all cabinet doors and rear sealing plates and lock them.

(2) Insert the operation handle of the grounding switch into the hexagonal hole on the lower right side of the middle door, turn it counterclockwise for about 90° to make the grounding switch in the opening position, take out the operation handle, the interlocking board at the operation hole will spring back automatically, cover the operation hole, and the switch cabinet rear door will be locked.

(3) Observe whether the instruments and signals of the upper cabinet door are normal.Normal microcomputer protection device power lamp on, hand test position lamp, circuit breaker opening indicator light and energy storage indicator light on, if all indicators are not bright, then open the cabinet door, confirm that the bus power switch is closed, if it has closed the indicator light is still not bright, then need to check the control loop.

(4) insert the circuit breaker handcart crank crank pin and press it hard, turn the crank clockwise, 6 kv switchgear about 20 laps, stuck in crank obviously accompanied by “clicking” sound when remove the crank, handcart in the job position at this time, a second plug is locked, loop through the breaker hand owners, see the related signal (at this point barrow position work lights,At the same time, the hand test position light is off), at the same time, it should be noted that when the hand is in the working position, the interlocking plate at the operation hole of the ground knife is locked and cannot be pressed

(5) operation instrument on the door, switch the circuit breaker switching power, instrument closing red indicator light on the door at the same time, the brake light green points out, check the electric display device, circuit breaker mechanical points location and other related signals, everything is normal, 6 (operation, switch, will show us the handle clockwise to panel location,The operation handle should be automatically reset to the pre-set position after release).

(6) if the circuit breaker is automatically opened after closing or automatically opened in operation, it is necessary to determine the cause of the fault and eliminate the fault can be re-transmitted according to the above procedure.

4. Circuit breaker operating mechanism

1, electromagnetic operation mechanism

Electromagnetic operating mechanism is a mature technology, the use of an earlier one kind of circuit breaker operating mechanism, its structure is simple, mechanical components number about 120, it is the use of electromagnetic force produced by the current in the closing coil drive switch core, impact closing link mechanism for closing, the size of its closing energy completely depends on the size of the switching current,Therefore, a large closing current is required.

The advantages of electromagnetic operating mechanism are as follows:

The structure is simple, the work is more reliable, the processing requirements are not very high, the manufacturing is easy, the production cost is low;

Can realize remote control operation and automatic reclosing;

It has good characteristics of closing and opening speed.

The disadvantages of electromagnetic operation mechanism mainly include:

The closing current is large, and the power consumed by the closing coil is large, which requires a high-power DC operating power supply.

The closing current is large, and the general auxiliary switch and relay contact cannot meet the requirements. Special DC contacter must be equipped, and the contact of DC contact with arc suppression coil is used to control the closing current, so as to control the closing and opening coil action;

The operation speed of the operating mechanism is low, the pressure of the contact is small, it is easy to cause the contact jump, the closing time is long, and the change of the power supply voltage has a great influence on the closing speed;

Cost of materials, bulky mechanism;

Outdoor substation circuit breaker body and operating mechanism are generally assembled together, this kind of integrated circuit breaker generally only has the function of electric, electric and manual points, and do not have the function of manual, when the failure of the operating mechanism box and the circuit breaker refused to electric, it must be blackout processing.

2, spring operating mechanism

The spring operating mechanism is composed of four parts: spring energy storage, closing maintenance, opening maintenance, opening, the number of parts is more, about 200, using the energy stored by the spring stretching and contraction of the mechanism to control the circuit breaker closing and opening.The energy storage of the spring is realized by the operation of the energy storage motor deceleration mechanism, and the closing and opening action of the circuit breaker is controlled by the closing and opening coil, so the energy of the circuit breaker closing and opening operation depends on the energy stored by the spring and has nothing to do with the size of the electromagnetic force, and does not need too much closing and opening current.

The advantages of spring operating mechanism are as follows:

Closing and opening current is not large, do not need high power operating power supply;

It can be used for remote electric energy storage, electric closing and opening, as well as local manual energy storage, manual closing and opening. Therefore, it can also be used for manual closing and opening when the operating power supply disappears or the operating mechanism refuses to operate.Fast closing and opening speed, not affected by the change of power supply voltage, and can fast automatic reclosing;

The energy storage motor has low power and can be used for both AC and DC.

Spring operating mechanism can make the energy transfer to obtain the best match, and make all kinds of circuit breaker specifications of breaking current common one kind of operating mechanism, choose different energy storage spring, cost-effective.

The main disadvantages of spring operating mechanism are:

The structure is complex, the manufacturing process is complex, the processing accuracy is high, the manufacturing cost is relatively high;

Large operation force, high requirements on the strength of components;

Easy to occur mechanical failure and make the operation mechanism refuse to move, burn the closing coil or travel switch;

There is a phenomenon of false jump, sometimes the false jump after the opening is not in place, unable to judge its combined position;

The characteristics of opening speed are poor.

3, permanent magnet operation mechanism

Permanent magnetic operating mechanism adopts the working principle and structure of a new, consists of a permanent magnet, closing coil and break-brake coil, cancelled the spring operating mechanism of the electromagnetic operating mechanism and movement, connecting rod, lock device, simple structure, very few parts, about 50, the main moving parts is only one at work, has the very high reliability.It uses permanent magnet to hold the position of circuit breaker. It is an operation mechanism of electromagnetic operation, permanent magnet holding and electronic control.

Working principle of permanent magnet operating mechanism:After the closing coil electricity, it on the top of generation and permanent magnet magnetic circuit in the opposite direction of magnetic flux, the magnetic force produced by superposition of two magnetic field makes the dynamic core downward movement, after the movement to about half the trip, due to the lower part of the magnetic air gap decreases, and permanent magnet magnetic field lines shifted to lower part, same direction as closing coil magnetic field with permanent magnet field, so that the speed of moving iron core downward movement,At this time, the closing current disappears. The permanent magnet uses the low magneto-impedance channel provided by the moving and static iron cores to keep the moving iron core in the steady position of closing.When break-brake coil electricity, it produced at the bottom of the magnetic circuit and permanent magnet in the opposite direction of magnetic flux, the magnetic force produced by superposition of two magnetic field makes the dynamic core upward movement, after the movement to about half the trip, due to the magnetic circuit upper air gap decreases, and permanent magnet magnetic line of force is transferred to the upper, the brake coil magnetic field with permanent magnet magnetic field in same direction, so that the speed of moving iron core upward movement,Finally reaches the fractional position, when the gate current disappears, the permanent magnet uses the low magneto-impedance channel provided by the moving and static iron cores to keep the moving iron core in the steady state of the opening.

The advantages of permanent magnet operating mechanism are as follows:

Adopt bistable, double coil mechanism.Permanent magnetic operating mechanism of points closing operation the closing coil, a permanent magnet to match the points closing coil, better solved the problem of the points when switching to high power energy, because of the permanent magnet with magnetic energy, can be used as a closing operation use, points to provide the energy for the closing coil can be reduced, so you don’t need too much points closing operation current.

By the up and down movement of moving iron core, through the turn arm, insulating rod ACTS on the dynamic contact of the circuit breaker vacuum arcing chamber, implement circuit breaker points or perform, replaced the traditional way of mechanical lock, mechanical structure is greatly simplified, reduce material, cost lower, reduce the fault point, greatly improve the reliability of the mechanical action, can realize the free maintenance, save maintenance cost.

The permanent magnetic force of the permanent magnet operating mechanism will almost not disappear, and the service life is up to 100,000 times. The electromagnetic force is used for opening and closing operation, and the permanent magnetic force is used for bistable position maintenance, which simplifies the transmission mechanism and reduces the energy consumption and noise of the operating mechanism. The service life of the permanent magnet operating mechanism is more than 3 times longer than that of the electromagnetic operating mechanism and the spring operating mechanism.

Adopt contactless, no moving components, no wear, no bounce electronic proximity switch as the auxiliary switch, there is no bad contact problem, reliable action, operation is not affected by the external environment, long life, high reliability, to solve the problem of contact bounce.

Adopt synchronous zero – crossing switch technology.Circuit breaker dynamic and static contact under the control of the electronic control system, can the system voltage waveform at each level, in the current waveform through zero at the break, the inrush current and over voltage amplitude is small, to reduce the impact on the grid and equipment operation, and the electromagnetic operating mechanism and operation of spring operating mechanism is random, can produce high inrush current and over voltage amplitude,Large impact on power grids and equipment.

Permanent magnet operating mechanism can realize local/remote opening and closing operation, also can realize protection closing and reclosing function, can be manually open.Because the operation of the required power capacity is small, the use of capacitors for the direct switching power supply, capacitor charging time is short, charging current is small, strong impact resistance, after the power cut can still be on the circuit breaker on and off operation.

The main disadvantages of permanent magnet operating mechanism are:

Can not manually close, in the operation of the power supply disappeared, capacitor power exhausted, if the capacitor can not be charged, it can not be closed operation;

Manual opening, the initial opening speed should be large enough, so it needs a lot of force, otherwise it can not be operated;

The quality of energy storage capacitors is uneven and difficult to guarantee;

It is difficult to obtain the ideal opening speed characteristic;

It is difficult to increase the opening output power of the permanent magnet operating mechanism.